What is a TDS?

How to read a powder coating technical data sheet

Technical Data Sheets (TDS)

Have you seen a TDS before? Not sure how to read it? Why are they important?

TDS are extremely important to understand before you start powder coating. Each sheet is specific to the powder you select and will give you all the information needed if you know how to read them.

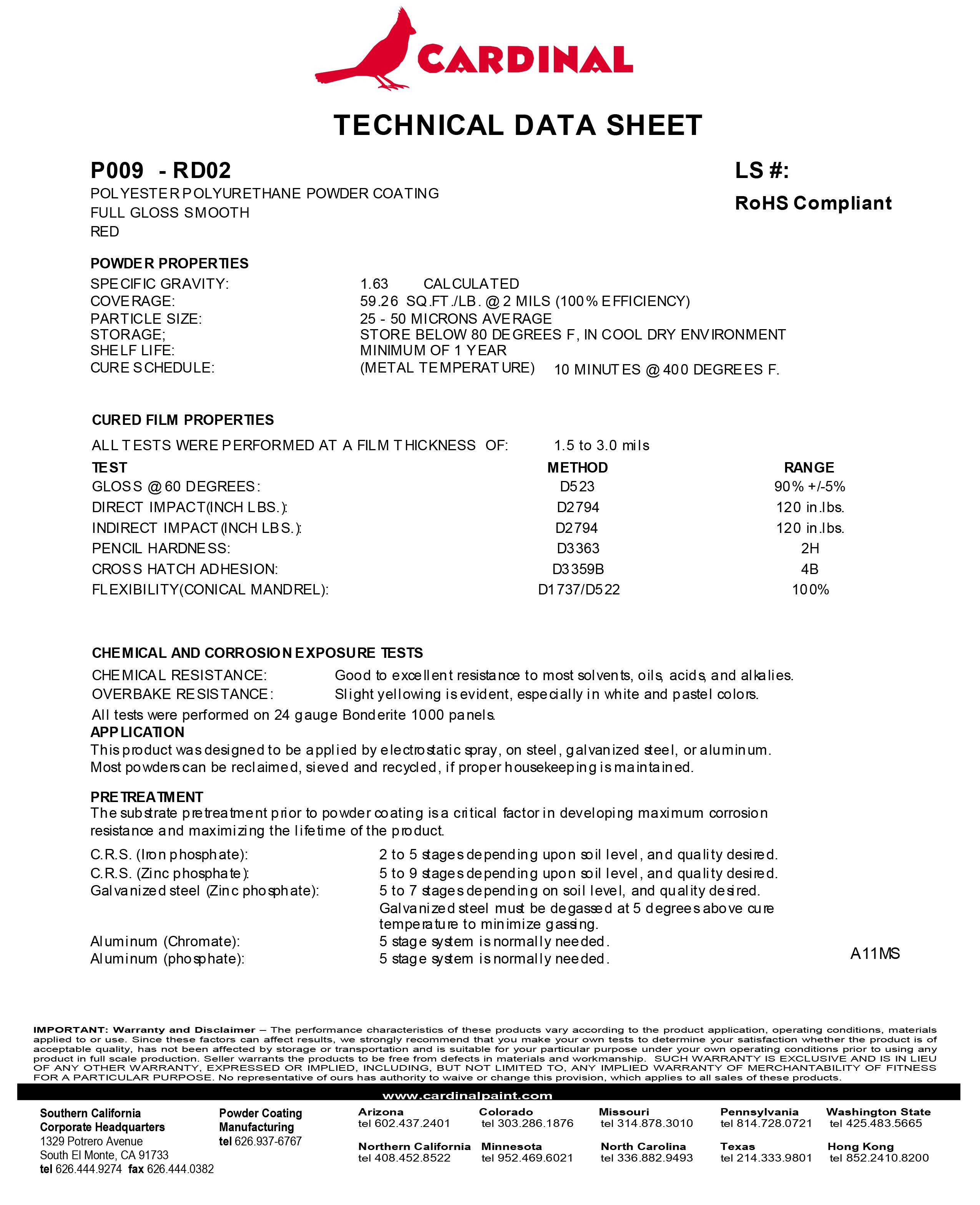

TDS Name, Type, Color

Each TDS regardless of the manufacturer will list the Name, Type and Color of the actual powder. The powder shown here (P009-RD02) is from Cardinal Powder Coating and listed as a Full Gloss Smooth Red. The Gloss level can be found under the Test area (Range) on the TDS sheet. The Red coating is listed as 90% +/-5%, which means if you follow the manufactures recommendations on the TDS, your part(s) coated will be anywhere from 85-95% gloss. Gloss level can depend on a lot of other factors including cure temperature and duration of cure.

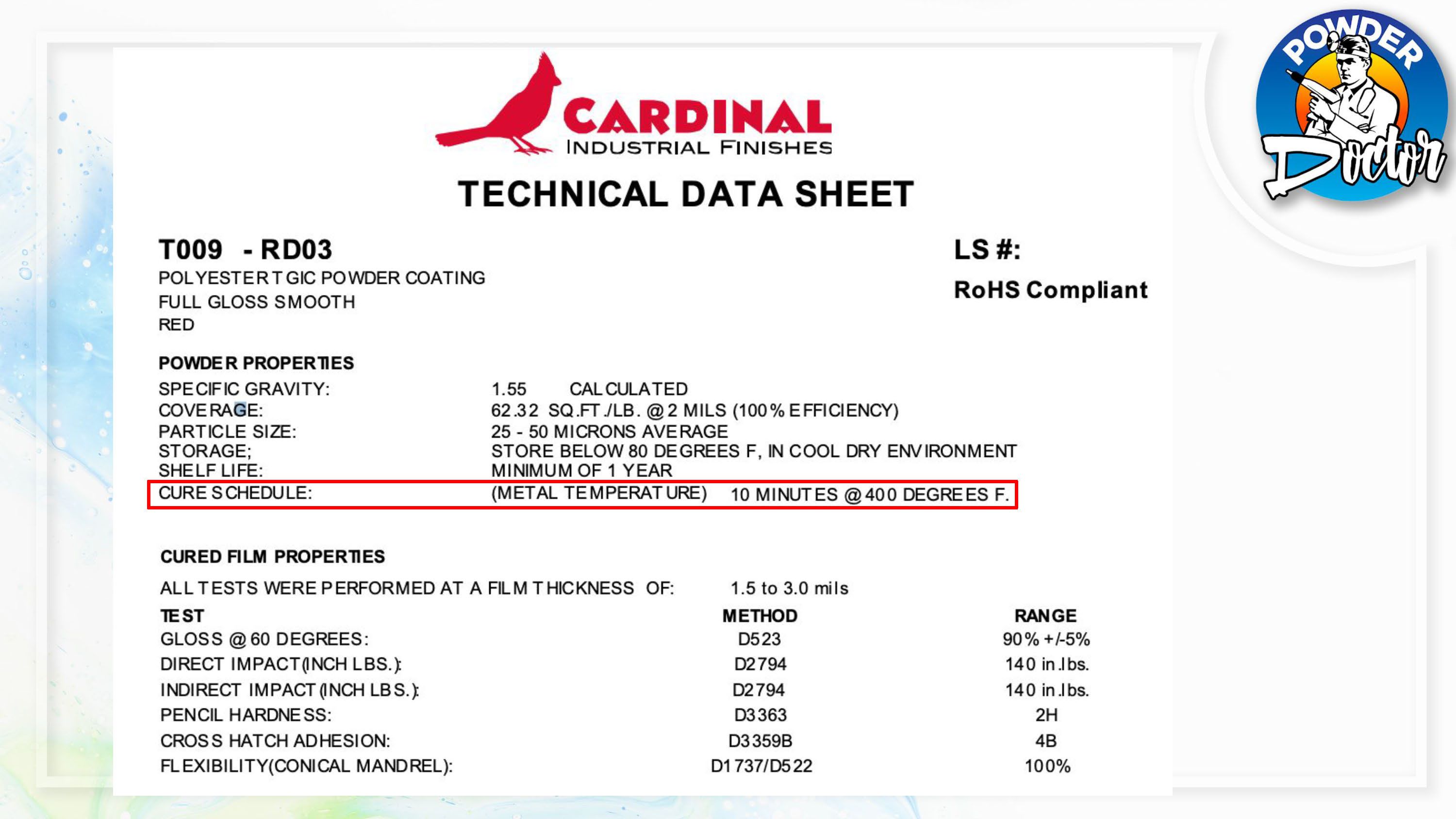

TDS Cure Time

Curing your part(s) correctly is vital to the longevity that powder coating offers. On the TDS you'll find a Cure Schedule or Cure Temperature and duration. Here the Cure Schedule is 10 minutes at 400 degrees Fahrenheit. This doesn't mean that you place your part(s) in the oven for 10 minutes at 400; it means you need to get your part(s) to 400, then start the timer for 10 minutes. Your parts must be at the temperature before the timer starts. Now that I say that, you can extend the time if you don't get your part(s) to temperature, but we are not going into that here. You should always try to follow the manufacturers TDS.

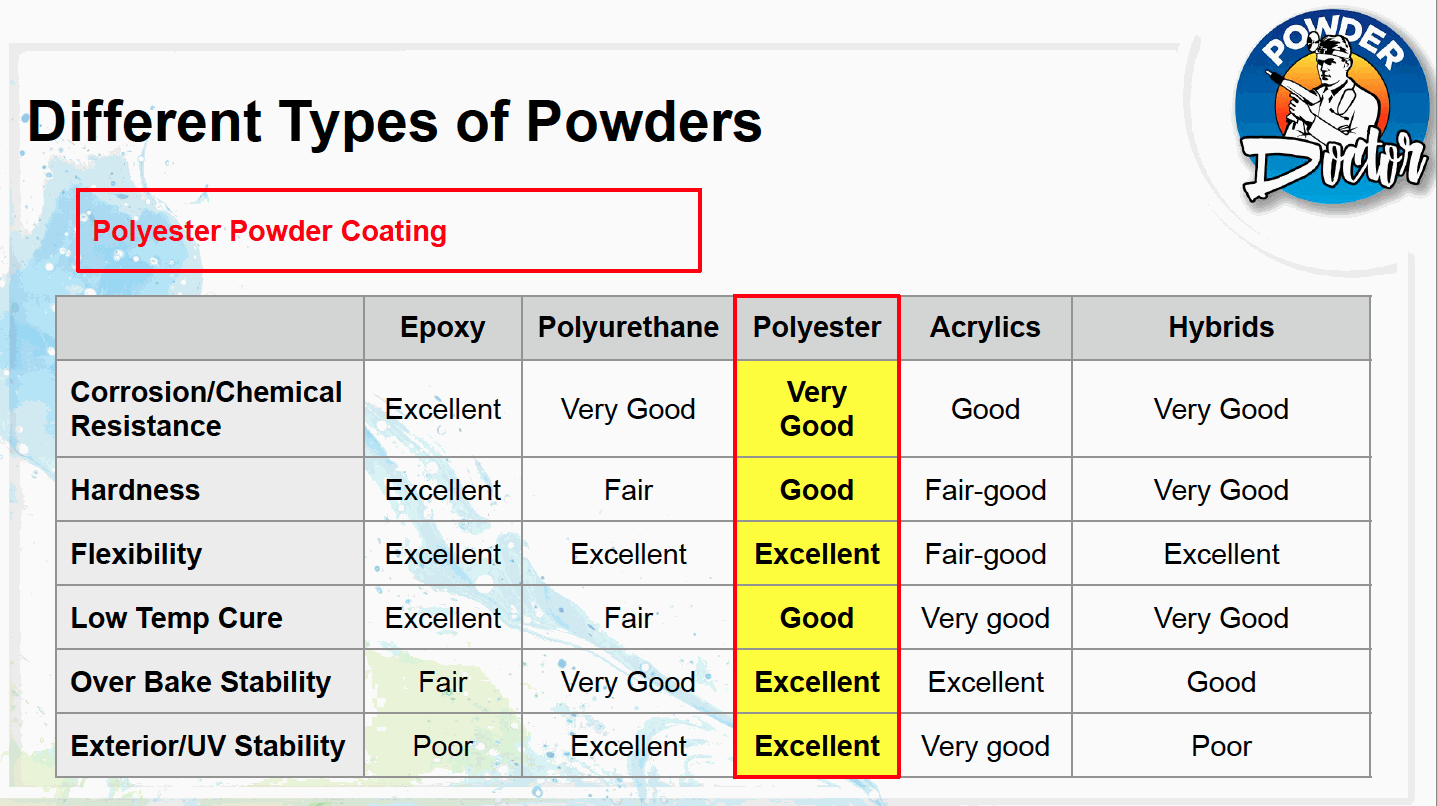

Powder Coating Types

Selecting the right type of powder is crucial to getting your part done right and for them to last. Based on the above TDS, the Red powder is listed as a polyester coating. As you can see from the chart showing different types of powder, polyester has very good corrosion resistance and a number of other good to excellent properties making it one of the work horse of most powder coating shops. Other coating types can give you different properties that may suit your needs for the environment and stress the part will endure during its life. Be sure to follow this chart to select the right type of powder for your part(s).